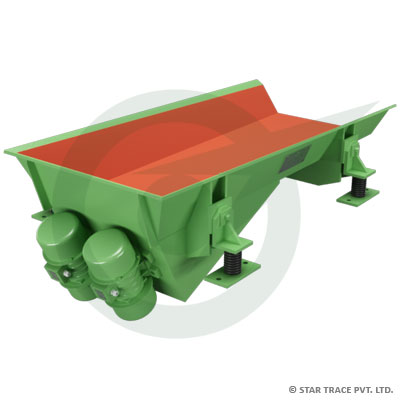

Vibratory Feeder

STAR TRACE Heavy-Duty Vibro Motor powered vibratory feeder is a high frequency reciprocating machine of heavy duty capable on conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow.Thus vibrating feeder are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various function like flow of material from storage, proportioning and blending, packing, mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc.

STAR TRACE Vibratory Motors used in vibro feeder are totally enclosed 3 phase, squirrel cage induction motors with adjustable, eccentric weights mounted at both the ends of the shaft to set up vibrations during rotation. The design of shaft and the selection of bearings has been carefully done to withstand heavy radial loads. Two identical motors mounted parallel to each other on a right and left, which is free to move in all directions, will produce linear vibrations. When connected for conta – rotation so know this principle is adopted for handling large bulky material in large feeders.

This Vibrator Motor stator frame is fabricated in steel or cost in spheroidal graphetic Iron and the windings / connections are properly reinforced to with stand the heavy vibrating forces. Vibrator motors can be adopted for conveyors and feeders for handling large quantities of materials is moved by linear force along with conveyor. Usually vibrator motors are fixed at an angle between 30o to 45o to the plane of the conveyor. This gives the system both upward and forward motion and horizontal vibrations to the tray which ensures a free, smooth, uniform and volumetric flow to the material that is fully variable.

STAR TRACE Heavy-Duty Vibrating Feeders are available in a variety of trough size and shapes as per IS:8723 1978. The vibratory tray is heavily fabricated duly stiffened with angles wear resistance plate can also be provided in the tray for varying abrasive materials. Tray can be made to suit individuals requirement. This can be made dust tight too.