Electrowinnings

Electrowinning, also called electroextraction, is the electrodeposition of metals from their electronics scrap that have been put in solution or liquefied.

In electrowinning, a current is passed from an inert anode through a liquid leach solution containing the metal so that the metal is extracted as it is deposited in an electroplating process onto the cathode.

In electrorefining, the anodes consist of unrefined impure metal, and as the current passes through the acidic electrolyte the anodes are corroded into the solution so that the electroplating process deposits refined pure metal onto the cathodes.

The precious metal operations consist of the smelter, the copper-leaching and electro winning plant and the precious metals refinery. The operations are designed in such a way that raw materials, can enter the flow-sheet at the most optimal process step. The smelter separates precious metals in a copper bullion, from mostly all other metals, concentrated in a lead slag, further treated at the base metals operations. After leaching out the copper in the leaching and copper electro winning plant, the precious metals are collected in a residue that is further refined at the precious metals refinery. The precious metals refinery combines different methods recover precious metals (silver (Ag) and gold (Au)) and platinum group metals (platinum (Pt), palladium (Pd), rhodium (Rh), iridium and ruthenium).

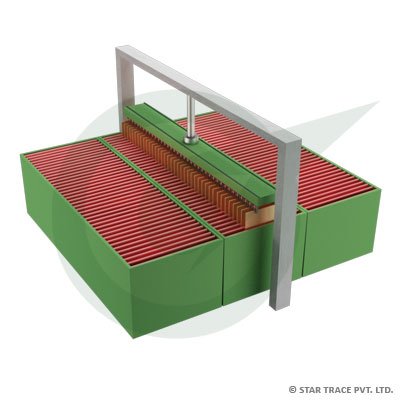

STAR TRACE offer a complete electrowinning to provide reliable and trouble-free operation for the entire life cycle of the plant.